Caltite Self‑Compacting Concrete

Rehabilitating & Waterproofing the Structure

The basement of a building at an education facility was deteriorated by soil water which caused sever water leakage from the basement floor and walls. To rehabilitate the basement, a special “waterproof” concrete mix was required.

Project Overview

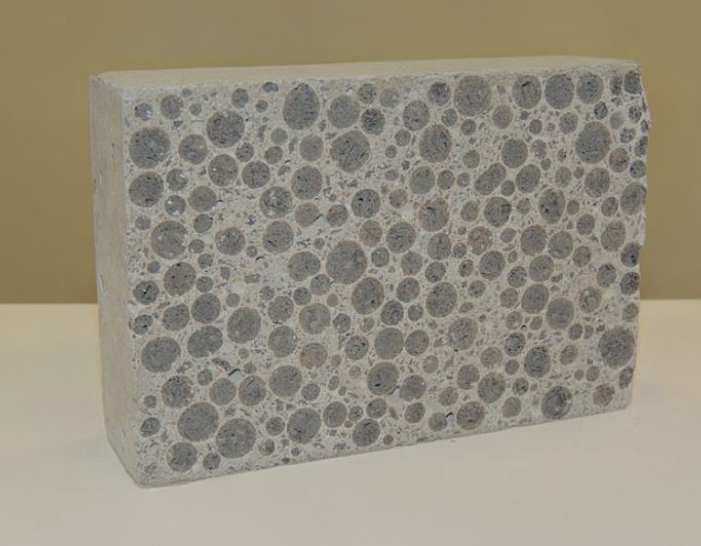

| Caltite concrete is a waterproofed concrete which reduces capillary water absorption as well as reduces permeability to water under pressure. Such properties allow waterproof concrete to be used in water-resisting construction below ground in place of water-proofing membranes. The particular mix design has not been used before in Saudi Arabia. |

Project Requirements:

- Target strength: 40 MPa @ 28 days

- High waterproofing properties: water absorption, according to BS 1881:122, less than 1%

- W/cm ratio: 0.35-0.40

- Wall jacketing, thickness around 15 cm

Challenges:

- Concrete floors and walls should be impervious to stop any ground water ingress

- Very thin reinforced sections with limited pouring points

- Very difficult to vibrate and compact of the placed concrete, especially in the walls

- Many openings, connections and pipes in the existing walls

- Difficult to reach by a mobile pump inside the existing basements

Solutions:

- Caltite (waterproofing admixture) was used in the mix design to meet the strict waterproofing requirements.

- Self-compacting concrete (SCC) with a 700 mm flow was the solution for pouring the very thin wall section without vibrators.

- The self-compacting concrete also acted as a self-leveling concrete for the basement floors to ensure easier and faster placing.

- Extension pipeline systems were used to deliver concrete from the mobile pumps to the basement.