Heavyweight Radiation‑Shielding Concrete

Imam Abdulrahman Bin Faisal University Hospital, Dammam, Saudi Arabia

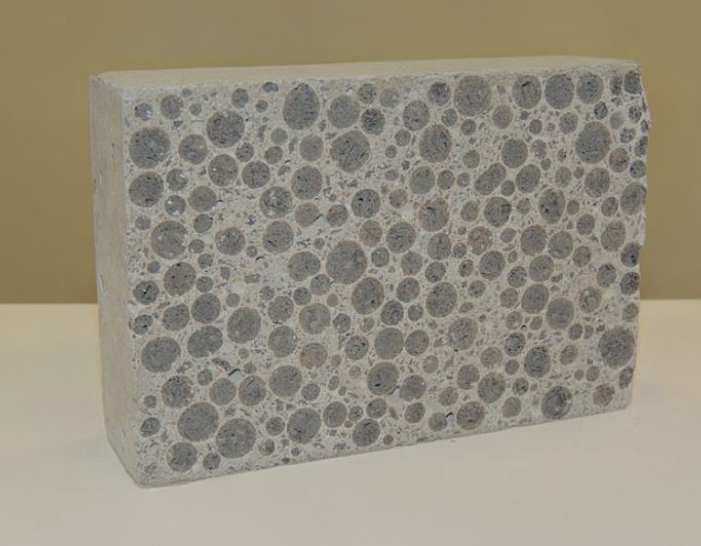

Heavyweight concrete is used primarily used for radiation shielding. Selection of concrete is based on space requirements and intensity of radiation.

Project Overview

| The Saudi Ministry of Higher Education is constructing a hospital at the University of Dammam, to provide special medical attention and support to the higher education sector. The project will see the construction of a medical tower 12 stories high, and house 400 beds. Among the rooms constructed at the hospital is a radiation treatment room. The room requires 1500m3 of heavyweight concrete with wall thicknesses ranging from 1.40m to 3.55m and slab thickness of1.6m. |

Project Requirements:

- Heavyweight concrete for radiation treatment room

- Compressive strength = 35 MPa

- Concrete density = 2,800 Kg/m3

- Slag aggregate gradation according to ASTM C537

Challenges:

- Produce heavyweight concrete with density 2,800 Kg/m3

- Control the heat of hydration in the large concrete sections and avoid the formation of thermal micro cracks

- Intense radiation shielding

- Find the right aggregate locally with required properties, gradation and density. The available slag aggregate in the market (only one supplier) is different from what ASTM 537 required

Solutions:

- Iron based slag (as coarse aggregate) was used for added weight and shielding effect.

- Several trial mixes were performed using the available slag aggregates to achieve the desired performance specification.

- A portion of the cement was replaced with supplementary cementitious materials (25% by weight) in the mix to reduce the heat of hydration while maintaining the required strength and sustainability.

- Heat of hydration was measured and simulated using special testing devices.