High Strength Concrete

General Organization for Social Insurance Towers, Riyadh, Saudi Arabia

The GOSI Olaya Tower Project with a total built-up area of approximately 250,000 m2 is a Class “A” state-of-the-art offices and commercial located on the junction of Olaya and Tahlia streets at the center of Riyadh. It consists of office premises, a lobby area connecting the two towers on the entrance level including two retail blocks above the ground level.

Project Overview

| The project has a (4) story underground car parking for 2400 cars with a total depth of 16m below ground level. Tower “A” consists of thirty-six (36) floors, and Tower “B” consists of thirty-four (34) floors, Facades of both towers are fully glazed and have office use levels, ground floor, mezzanine floor, technical floor, lift floor, roof, and upper roof structures. |

Project Requirements:

The target was to produce concrete for columns and walls for the buildings with the following characteristics:

- Design strength = 70 MPa @ 90 Days.

- Concrete with a flow of 550±50mm for high-rise pumping should have.

Challenges:

- The meager water-cement ratio needed to achieve the targeted strength and flowability

- Increased water demand due to the use of Micro Silica

- Due to the severity of the site location flowability retention for 90 min

Solutions:

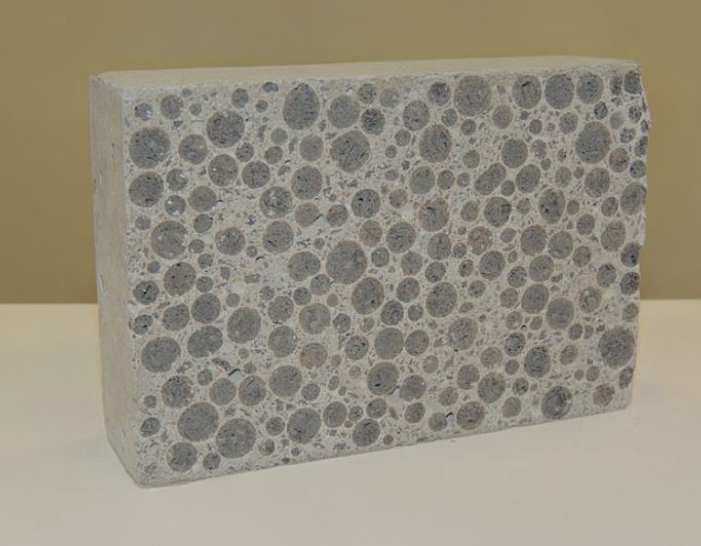

- Using Micro Silica to improve the ultimate strength and permeability by reducing bleeding and segregation and by increasing cohesiveness of the mix.

- Using Ultrahigh range water reducers to achieve the required characteristics.