Readymix Mortar

Rafal Tower, Riyadh, Saudi Arabia

In order to provide high-quality accommodation in the heart of the capital city of Saudi Arabia, Rafal Real Estate Development Company is constructing a 62 story commercial and housing tower.

Project Overview:

| The development is located where the Assahafa District meets the King Fahad Highway in Riyadh, covers an area of 20,000 m² (sqm) and is to include 300 luxury guestrooms and suites. The location is destined to be one of the most desirable addresses in Riyadh as a vibrant residential and business hub, in essence a self-sustained community, where residents and visitors will enjoy an incomparable 365 days of quality lifestyle a year, an ideal balance of tranquility and modern convenience. Its tower, the Rafal Tower, is to stand at 308 m high and be the tallest building in Riyadh for a while. |

Project Requirements:

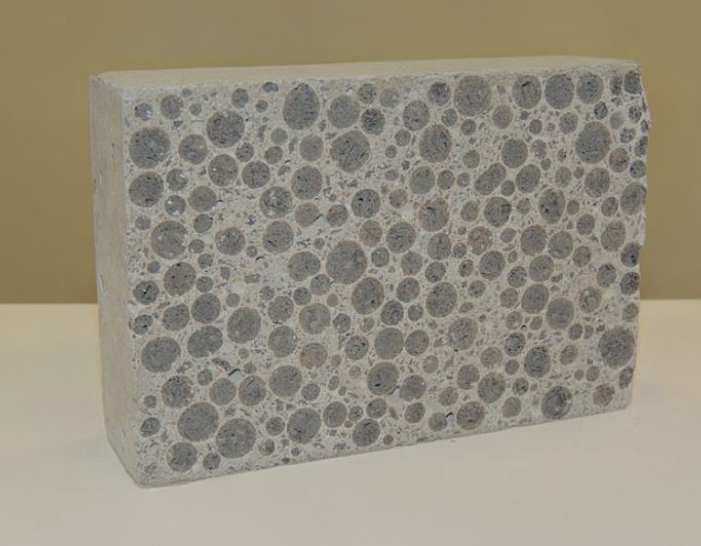

Due to the large quantity of mortar needed for a number of applications, and increase efficiency while reducing loss of material, Saudi Readymix was hired to produce and deliver ready-mixed mortar for the project (under the following requirements):

- The mix is to be suitable for all mortar uses in the project such as, but not limited to, plastering, block and tile works.

- It needs to have a prolonged setting time for the mix to remain workable for an extended period and to ensure that the necessary quantities are delivered to the site in one trip per day.

- Lastly, it should harden quickly after used in work.

Challenges:

- This was the first time such a mix is produced in Saudi Arabia (no past experience or local record on the subject).

- The client insisted that the mortar should be suitable for all uses.

- The nature of the mix is very sensitive to environmental factors (namely, wind and temperature reduce the setting time significantly).

- Delivery then placing and storing the mix at different locations around the site area and distributed evenly and close to all workers.

Solutions:

- To resolve the issue of first time mix, Saudi Readymix conducted a lot of experiments and tested plenty of trial mixes and mix designs to reach the desired results.

- A special type of chemical admixture was discovered and used to produce a mix that has a minimum setting time of 36 hours.

- Special cube shaped containers 0.5m³ thick were used to store the mortar at the site. The containers allowed for the mortar to be moved, lifted and stored to, and on, different locations on site.

- To prevent the loss of moisture in the mix, the containers were lined and covered with nylon (cling/PVDC) sheets.