Roller Compacted Concrete

King Abdullah Port, King Abdullah Economic City, Rabbig, Saudi Arabia

The project calls for the construction of a 2.6 million square meter seaport, named King Abdullah Millennium Seaport, strategically located on the Red Sea with ease of access to key cities within Saudi Arabia.

Project Overview:

| King Abdullah Port, part of the wider King Abdullah Economic City Project (the largest of its kind in the gulf region), is a state-of-the-art container port with a capacity of 3.8million TEU/year in Phase 1 (increasing to 6 million TEU/year in Phase two) and set to become one of the large seaports in the world similar in size to Rotterdam and capable of handling even the largest super vessels. The port will also provide a dedicated Haj Terminal to cater for an estimate 500,000 pilgrims every season along with integrated transport links, high speed rail, hotels and healthcare facilities. The roller compacted concrete quantity required for the project is estimated to be, at least, 500,000 m3. |

Project Requirements:

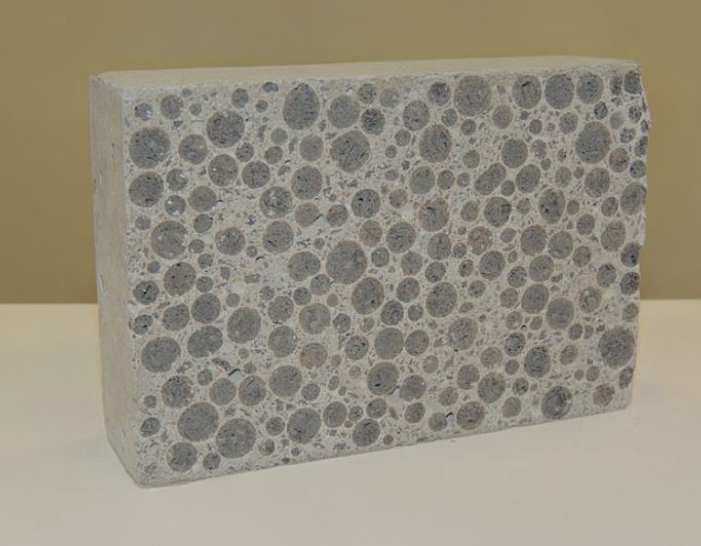

- Semi-dry roller concrete.

- Maximum Cube Strengthof 21 MPa.

- Portland cement content of 175 kg.

- Water to Cement Ratio (W/C) of 0.86

Challenges:

- Using an unconventionally lower cement content, yet still achieving required strength.

- Manipulating the mix to control its loss of moisture and create a workable mix for a specific surface finish, or monitor the concrete and its moisture once placed.

- Factories are equipped with Ton Shaft mixers or Pan mixers, whereas this mix requires drum mixers.

- Produce 500 K m3 within 2 years.

Solutions:

- Moisture loss was monitored, and adjusted, after placement of concrete.

- Several trial mixes were experimented with, including the standard drawing curves and aggregate combinations along with testing different admixtures.

- A Drum mixer batch plant was installed on-site to produce the roller compacted concrete.