Slip Form Concrete

Al-Majdoul Tower, Riyadh, Saudi Arabia

Majdoul Tower is a 50 story office tower under construction on podium in the City of Riyadh. The building site was designed in coordination with Zeidler Partnership Architects to complement the contemporary sculptural expression of the building.

Project Overview

| The site design includes a diverse layer of elements including building canopies, tree bouquets, cascading reflecting fountains and extensive lighting which respond to its cultural and climatic setting, allowing for pedestrian activity not only throughout the day, but also in the evening. MESA’s dynamic use of materials highlight the refined forms used to create spaces capable of supporting large events as well as intimate meetings and moments of personal reflection. The spaces create versatile experiences from an elegant plaza to a secluded private garden; however the design is not only to be experienced and appreciated by pedestrians on the ground level, but also people viewing the site from the roof garden above. |

Project Requirements:

The target is to produce concrete for core wall of the building. The wall is being constructed using slip-form technique therefor the concrete should have the following characteristics:

- Design strength = 56 MPa @ 56 Days.

- Slump at lower levels 250±50mm

- Slump flow at higher levels will be modified to 550±50mm to allow for high-rise pumping.

- Minimum initial setting time = 6 hours to allow for installation of the remaining steel bars.

Challenges:

- The low water cement ratio needed to achieve the targeted strength.

- It is difficult to produce flow-able at such water cement ratio.

- The risk of low strength at early ages due to the amount of retarder needed to maintain setting time at the needed limit.</

- Due to the sensitive condition of such structural element it is important to maintain continuous delivery of concrete and that will be hard because of the project location and congested traffic around it.

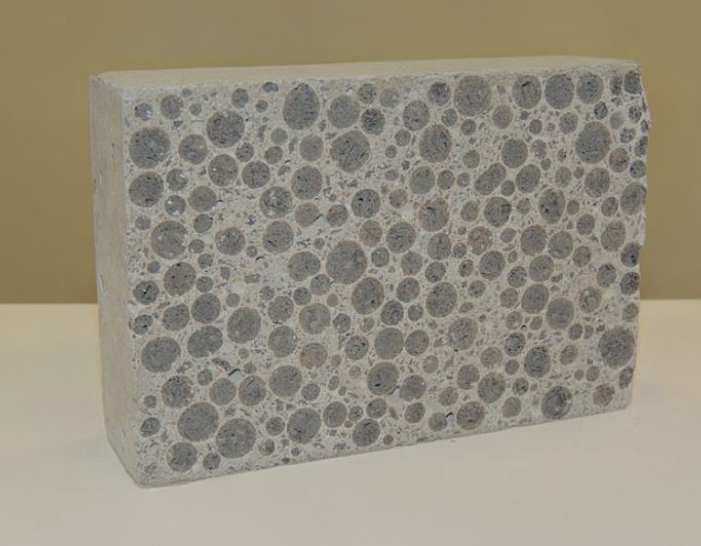

- Formation of deformed surface after lifting the slip form.

Solutions:

- Using high range water reducers to achieve the required characteristics

- Choose time of casting where the traffic is at minimum levels to insure the continuous delivery

- Using good coating material to prevent the formation of deformed surface