Special Concrete for Sulphur Pit Concrete

Saudi Aramco Gas Plants, Jubail Industrial City, Saudi Arabia

A special concrete for sulfur pit construction of Saudi Aramco gas plants has been requested by Isam Kabbani Group to be delivered to two locations in eastern region of Saudi Arabia. The first plant is Berri Gas Plant located in Jubail city with total quantity of 675 m3 , the second one is Shedgum Gas Plant located in Hafouf city with total concrete quantity of 650 m3.

Project Overview

| For Saudi Aramco gas plants at Berri (Jubail) and Shedgum (Al-Hofuf), Saudi Readymix delivered a specialized flowable concrete mix tailored for sulphur pit construction. The project involved supplying 675 m³ and 650 m³ respectively, featuring a ternary mix with GGBFS, silica fume, non-calcareous aggregates, and W/CM ≤ 0.36. The self-compacting design delivered exceptional flowability (slump flow ≈ 650 ± 65 mm), minimized segregation and achieved high 56-day compressive strength (60 MPa with ≥ 8 MPa safety margin) and low permeability (RCP charge < 1000 coulombs, water absorption < 1.2%). Advanced mix development, logistics for long-distance aggregate sourcing, and rigorous pre-pour and lab testing ensured success across both remote sites. |

Project Requirements:

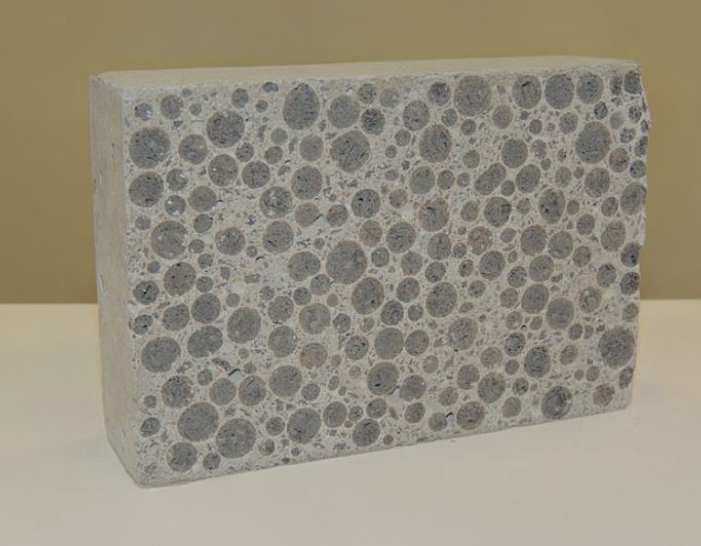

Requirements of Mix ingredients and Proportions:

- Ternary mix with the use of GGBFS and Silica fume

- Non-calcareous aggregates

- Maximum W/CM ration = 0.36

Requirement of Fresh Concrete Properties: Self-competing concrete with the following properties:

- Slump Flow: 650±65 mm at 2 hours

- Static segregation index: 0 to 3.8% according to ASTM C1610

- J-ring test: Passing Ability < 25 mm according to ASTM C1621

Requirements of Hardened Concrete Properties:

- High strength concrete: 60Mpa at 56 days with a safety margin not less than 8 MPa

- RCP charge less than 1000 coulombs at 56 days according to ASTM C1202.

- Water Absorption less than 1.2% according to BS 1881-122

Challenges:

- Developing of self-compacting concrete which meets with the project requirements for far-distance sites. Track mixer takes more than 75 minutes to reach the project site.

- Self-competing concrete with a high pump-ability property which it has to facilitate pumping of the concrete without blockage, segregation or major loss in slump flow.

- Producing of a concrete with challengeable durability requirements.

- Use of a high quality non-calcareous aggregate: this type of aggregate is not available in eastern region of Saudi Arabia. It should be transported from western region to the locations of batching plants with a consistent highly quality to ensure the quality of the finished project and a constant supply to ensure on-time delivery.

Solutions:

- Moisture loss was monitored, and adjusted, after placement of concrete.

- Several trial mixes were experimented with, including the standard drawing curves and aggregate combinations along with testing different admixtures.

- A Drum mixer batch plant was installed on-site to produce the roller compacted concrete.