Steel Fiber Concrete

SIBCO Mega Plant, Jeddah, Saudi Arabia

The project calls for the construction of an Industrial station in the second industrial city in Jeddah south. The project commissioned by the Saudi Industrial Beverage Company (SIBCO). In the site an area of requires 7,331m²of Steel Fiber Reinforced Concrete Raft Foundation.

Project Overview

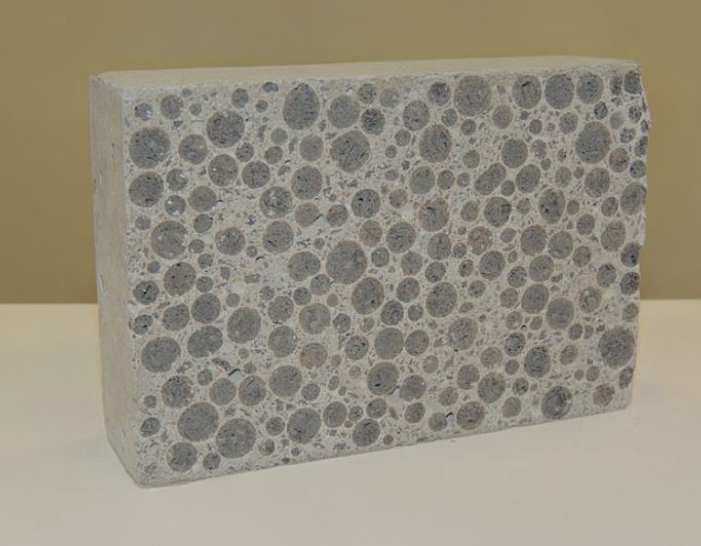

| The area of the Foundation has been divided into 12 squares, with 500 m3 concrete per each square, with the total concrete quantity for the foundation around 5500 cubic meters using the steel fiber 4D type. By choosing a Steel Fiber design, we managed to eliminate approximately 40 tons per panel of traditional steel reinforcement and replaced it with 30 kg’s/m³ of the Bekaert, Dramix 4D 65/60 BG Steel fiber. Due to the effectiveness of the Reinforced Concrete Raft design and the fact that the Steel Fiber reinforces the full depth of the slab the original design thickness of 1.2 m’s was reduced to 0,70 m, equivalent to a total saving of a 3,655m³ of concrete. To accommodate the requirements of this facility, the Foundation was designed, according to the internationally recognized FEM 9.831 Standards and the Saudi building code SBC-301 that provides for local load factors and load combinations such as wind loads and earthquake requirements. |

Project Requirements:

- Target Strength = 35 N/mm2 @ 28 days

- Recommended slump to be in 200 mm before pumping

- 280 mm initially, 250 after 40 minutes and 240 after adding the fibers

- Steel fiber type is 4D 30kg/m

Challenges:

- Achieve the Strength @ 28 days using the steel fiber

- Pump blockages during trial mixes relating to steel fiber which can take 4 hours to be cleared/li>

- Concrete slump reduction after adding the steel fiber about 40 mm less than needed

- Handling of steel fibersTime lost due to the slow process of Conveyer pumping

Solutions:

- Individual pumps used for pumping this concrete called “conveyers” were used to solve pumping problems.

- Optimizing the mix to achieve the required target slump using Admixtures (W-8, and D-156) in batch plant and at the site to be 240 mm after adding the fibers.

- Steel fiber concrete is relatively new and unknown in Saudi Arabia, and specialized equipment in the batch plant had to be installed, Steel fibers were added on site in every mixer by dedicated people from RCR Company. It took 10-15 minutes per mixer to add the total quantity of steel fibers.

- One more conveyer than usual has been used to speed the pumping process.

- Despite clogged SRMCC pumps, we used two pumps to speed the work, and because of losing one conveyor, three technicians were always present beside each pump to remove the usual concrete clumps, steel fibers tend to create.