How It Works

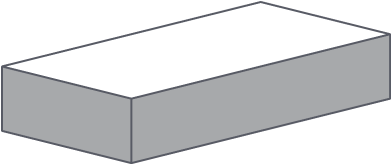

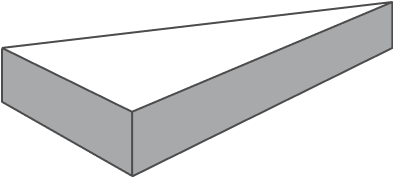

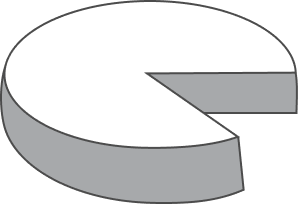

- Select a Shape – Choose from rectangle, triangle, or circle.

- Enter Dimensions – Input width, length, and depth.

- Calculate Volume – Click “Calculate” to get the required concrete in m³.

- Add More Shapes – Use “Add another shape” for multiple areas.

- Total Volume – The tool sums all shapes for total concrete needed.

Note – Add 5–10% extra to account for spillage and site variations.

Choose Shape A

Volume

0 m³

Formula Aggregates Tonnes

0.00 t

Total Volume

0 m3

How Much Concrete Do You Need ?

Concrete volume accuracy is critical in every construction project. This calculator helps you estimate the exact amount of ready-mix required based on your structure’s length, width, and depth.

Whether you’re working on foundations, walls, slabs, or columns — plan smarter, reduce costs, and ensure you have just the right amount of material on site.

Key statistics

Accurate Volume Estimation

Delivers precise results for reliable project planning.

Expert Guidance On Demand

Get technical support from our concrete specialists.

Reliable Industry Partner

Backed by Saudi Readymix’s trusted supply network.

Need Technical Support?

Our team is here to assist you with any questions related to specifications, volume calculations, or product suitability.

Reach out today and get expert advice fit to your project’s needs.